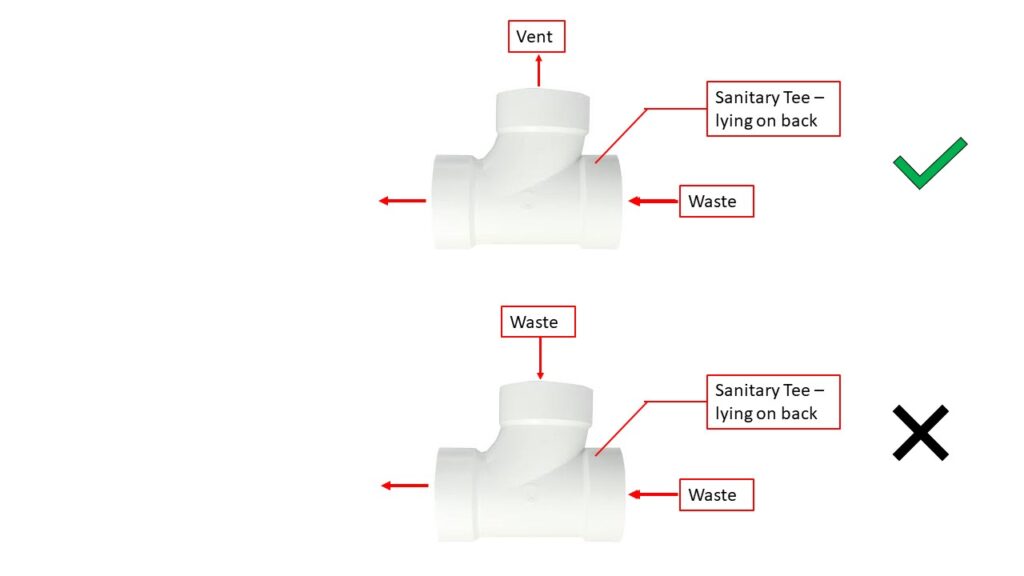

Incorrect use of sanitary tee fittings in drainage systems is a common problem. What is the proper use of sanitary tee fittings in plumbing DWV piping? Table 706.3 of the IPC provides the code requirements for correctly using plumbing fittings.

[Read more…]