When are thermal expansion tanks needed and/or required in plumbing systems?

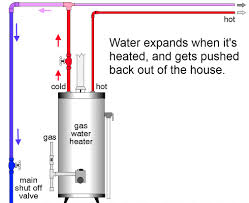

When heated, water expands. We know that. When water is heated in a water heater, the water expands, if possible. But what happens when water is heated in a water heater and there is no hot water usage?

This can occur after a period of showering/bathing during peak times followed by a period of no hot water usage. For example, evenings are a time when there is hot water usage for showering followed by a period of no usage while people are sleeping during the night.

During peak usage times, hot water stored in the water heater is distributed to the end-users, and cold water fills the water heater. The cold water in the tank is then heated, but when there is no subsequent hot water usage, the heated water has no room for expansion. If there is no place for the expanded water to go, the pressure in the system increases significantly. This leads to one of two possible scenarios:

1. The heated water expands back into the cold water supply. The hot water will expand back into the cold water supply if there are no restrictions, such as check valves, in the supply line. When this occurs, hot water can come out of a cold water faucet. This can be disturbing and surprising to the user, at best. If the hot water is from a high-temperature source, like 1400F hot water for a commercial kitchen, a scalding incident can occur at a cold water faucet!

1. The heated water expands back into the cold water supply. The hot water will expand back into the cold water supply if there are no restrictions, such as check valves, in the supply line. When this occurs, hot water can come out of a cold water faucet. This can be disturbing and surprising to the user, at best. If the hot water is from a high-temperature source, like 1400F hot water for a commercial kitchen, a scalding incident can occur at a cold water faucet!

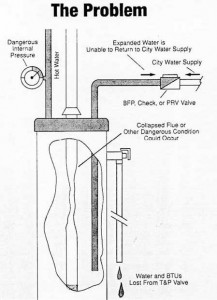

2. If there is a check valve in the cold water supply line to the water heater, there is no opportunity for the heated water to expand. The pressure then rises in the water heater and lifts the pressure-relief valve. This relieves the excessive pressure, but repeated pressure excursions and relief valve operation reduces the system integrity, results in leaking relief valves, and wastes water and energy.

2. If there is a check valve in the cold water supply line to the water heater, there is no opportunity for the heated water to expand. The pressure then rises in the water heater and lifts the pressure-relief valve. This relieves the excessive pressure, but repeated pressure excursions and relief valve operation reduces the system integrity, results in leaking relief valves, and wastes water and energy.

When pressure can increase in a plumbing system from thermal expansion, the International Plumbing Code (IPC), the Uniform Plumbing Code (UPC), and the Standard Plumbing Code all require a device to be installed to control the pressure. For example, the 2012 IPC Paragraph 607.3 states:

607.3 Thermal expansion control. A means of controlling increase pressure caused by thermal expansion shall be provided where required in accordance with Sections 607.3.1 and 607.3.2.

607.3.1 Pressure-reducing valve. For water service system sizes up to and including 2 inches, a device for controlling pressure shall be installed where, because of thermal expansion, the pressure on the downstream side of a pressure-reducing valve exceeds the pressure-reducing valve setting.

607.3.2 Backflow prevention device or check valve. Where a backflow prevention, check valve or other device is installed on a water supply system utilizing storage water heating equipment such that thermal expansion causes an increase in pressure, a device for controlling pressure shall be installed.

This code language requires a device to be installed when thermal expansion can cause the pressure to exceed the set point of a pressure-reducing valve. Setpoints of pressure-reducing valves on the system supply can be no higher than 80 psi and often come factory preset at 50 psi.

A device is also required to control thermal expansion when there is a backflow preventer or check valve installed on the water supply system. Commercial facilities typically have a backflow preventer on the system supply. Backflow preventers prevent water from flowing back into the city main, protecting the water quality of the municipal water supply. These valves also prevent water from thermal expansion from flowing back into the municipal supply, resulting in excessive pressure buildup.

These two code requirements essentially require a device to be installed in most commercial plumbing systems to control thermal expansion. The device to control thermal expansion can be a thermal expansion tank or a relief valve.

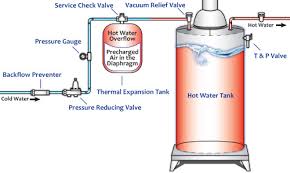

A thermal expansion tank is also a device designed to prevent an increase in pressure from thermal expansion. The expansion tank has a rubber diaphragm that is pre-charged with air on one side. System water fills the tank on the other side of the rubber diaphragm. Since air is a compressible fluid, as the water pressure increases from thermal expansion, the diaphragm pushes against the air cushion, which compresses and provides additional space for the water to expand. The expanded water is contained within the system, and the pressure is controlled.

A thermal expansion tank is also a device designed to prevent an increase in pressure from thermal expansion. The expansion tank has a rubber diaphragm that is pre-charged with air on one side. System water fills the tank on the other side of the rubber diaphragm. Since air is a compressible fluid, as the water pressure increases from thermal expansion, the diaphragm pushes against the air cushion, which compresses and provides additional space for the water to expand. The expanded water is contained within the system, and the pressure is controlled.

There are also two types of relief valves that are designed to prevent pressure buildup from thermal expansion.

- Pressure-reducing valves can be provided with a thermal expansion bypass. The built-in thermal expansion bypass operates on the principle of a check valve in reverse. The internal check valve normally prevents any reverse flow of water back into the system main. When thermal expansion pressure increases to just 1 lb. to 2 lbs. higher than the main pressure, the check valve opens passing the expanding water back into the supply main at the rate it is expanded. This type of valve is only helpful when there is no backflow preventer at the system main. A backflow preventer is typically required, however, on most commercial facilities.

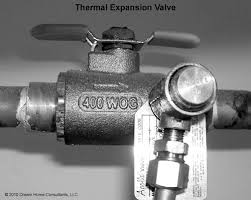

Combination ball valves with relief valves are also available. These valves are designed to be used as the isolation valve in the cold water supply to the water heater. They provide both a means to shut off the water supply to the water heater and to provide protection against excess water pressure caused by thermal expansion. One disadvantage of combination ball and relief valves is that the thermally expanded water is removed from the system. This wastes water and energy. Also, a drain line is required to route the discharge to a safe location. The discharge from the relief valve port can be routed to a floor drain, to the water heater drain pan, or to the exterior. Although the IPC does not provide specific details about where to terminate the relief valve discharge, I follow the requirements given in the code for water heater relief valves.

Combination ball valves with relief valves are also available. These valves are designed to be used as the isolation valve in the cold water supply to the water heater. They provide both a means to shut off the water supply to the water heater and to provide protection against excess water pressure caused by thermal expansion. One disadvantage of combination ball and relief valves is that the thermally expanded water is removed from the system. This wastes water and energy. Also, a drain line is required to route the discharge to a safe location. The discharge from the relief valve port can be routed to a floor drain, to the water heater drain pan, or to the exterior. Although the IPC does not provide specific details about where to terminate the relief valve discharge, I follow the requirements given in the code for water heater relief valves.

In general, I believe the best method to control thermal expansion from heated water in a water heater is to install a properly sized thermal expansion tank in the cold water supply to the water heater. There are special situations, however, when a thermal expansion valve is a good option. I have used them when a small water heater is installed in a cabinet or small closet where space is limited.

For topics on future blog posts, make a suggestion.

Hi Roger,

First of allí, thanks for the post, it is very interesting.

I want to ask you for a doubt. I have been researching the best location for the expansion vessel and most of the articles explain the same as you. Expansion vessels shoul be localed in the cold line. But I haven’t find the reason.

Why is this?

Thanks!

Jorge Sánchez

Jorge,

The thermal expansion tank can technically be located on either the cold or hot water side of the water heater. However, hot water will shorten the life of the rubber diaphragm in the expansion tank. For this reason, the cold water supply line is the preferred location.

Hope that helps,

Roger

Hi Roger,

Many thanks for tour help!

Regards,

I can see in manufacturers manual that there are 2 models of expansion tank.

1. Vertical mount

2. Horizontal mount

My question is, Can a vertical mounting tank be placed horizontally??

If the manufacturer’s instructions state that the tank must be mounted vertically, I would not mount it in the horizontal orientation. Plumbing codes and project specifications typically require equipment to be installed in accordance with the manufacturer’s instructions.

Some manufacturer’s allow their expansion tank to be installed in either orientation, (e.g. Watts). The important thing to keep in mind is, if you mount a tank in the horizontal orientation, it should be supported from the structure. If the rubber bladder fails, the entire tank will fill with water. When this occurs, the weight can cause the piping or fitting of an unsupported tank to fail and flood the building.

Roger