Thermal expansion tanks are typically installed in conjunction with storage water heaters, but are they needed with tankless water heaters? This issue can sometimes be overlooked. Let’s look at the specifics.

Code Requirements

Section 607.3 of the 2012 International Plumbing Code (IPC) provides the requirements for controlling pressure caused by thermal expansion. The requirements contained in paragraphs 607. 3 and 607.3.1 do not specifically distinguish between thermal expansion from a storage water heater, a tankless water heater, or other system equipment. Paragraph 607.3.2 does specifically require a device for controlling pressure “when there is a backflow prevention device, check valve or other device installed on the water supply system utilizing storage water heating equipment such that thermal expansion causes an increase in pressure.”

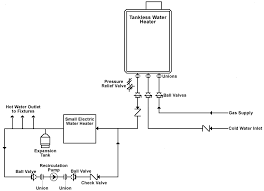

The IPC does not specifically require a thermal expansion tank to be installed with tankless water heaters. However, if a storage tank is used in conjunction with a tankless water heater in a closed system, which is sometimes the case with recirculation, then a means of controlling thermal expansion must be provided.

Here is a thorough explanation provided in the 2012 IPC Code Commentary.

Note that this section (607.3.2) identifies only “storage water heating equipment” as the generator of hot water. While this appears to imply that thermal expansion-induced pressure increases are only created by storage tank water heaters, this is not the case. A question that is frequently asked is, “Does a water distribution system with tankless water heater require control of pressure increases caused by thermal expansion?” The answer is provided in the following two examples.

System A: Water distribution system with a tankless, on-demand water heater (electric or gas) without a storage tank. In this system, water is heated only when a hot water outlet is open. Because the water distribution system is now an “open” system (i.e., a hot water outlet is open), any thermal expansion is relieved through the open hot water outlet and no pressure increase can occur. When the outlet is closed, the system becomes a closed system but, since the flow has ceased, the tankless water heater stops heating the water. Therefore, methods for controlling pressure increases due to thermal expansion are not required.

System B: Water distribution system with tankless, on-demand water heater (electric or gas) with a storage tank. The water service line has a backflow preventer (such as a dual check valve at the water meter). In this system, an unfired hot water storage tank may be required to provide for hot water recirculation to lessen the “wait time” for hot water to arrive at any fixture. Or the storage tank might be required to provide for large simultaneous hot water demands (that the tankless water heater cannot produce without the storage). For either reason, as the hot water storage tank cools off, a circulation pump is switched on to cause flow out of the storage tank, through the tankless water heater and back into the storage tank until the water in the storage tank is at an acceptable temperature level. Because there will be times where no hot water outlet is opened during the time that the tankless water heater is heating water, the water distribution system is a “closed” system, therefore, a means for controlling pressure increases due to the thermal expansion must be provided.

Note: The Uniform Plumbing Code requires thermal expansion tanks if there is a check valve, pressure regulator, or backflow preventer installed in the main supply line, regardless of the type of water heater. So the adopted municipal code must be determined to ascertain whether a thermal expansion tank is required.

Closed Systems – Recirculation

When there is a closed system with a heating source, there is a potential for pressure increases from thermal expansion. This is the case with tankless water heaters installed with a recirculation loop and a storage tank. Therefore, a device, such as a thermal expansion tank, must be provided to control the potential pressure increase.

Note: The pressure relief valve on a water heater cannot be used as the device to control the pressure.

Buffer Tanks

Newer models of tankless water heaters can have integral buffer tanks. These tanks are small (1 – 2 gallons), but they can create high system pressure due to thermal expansion. If a tankless heater has an integral buffer tank, a thermal expansion tank should be included in the system design to prevent overpressurization.

Are there other situations that you have encountered where thermal expansion tanks are needed with tankless water heaters?

For suggestions on future blog posts, make a suggestion.

Does it matter where the expansion tank goes? Can it be on the cold water supply line, or does it have to go on the hot water or recirc line?

From the standpoint of thermal expansion, the location does not matter as long as there is not a check valve between the water heater and the thermal expansion tank.

The cold water supply line near the water heater is the preferred location though. When located in the cold water supply line, the operating temperature of the thermal expansion tank is lower, resulting in a longer life for the tank.

This is an eye-opener for homeowners like me who have tankless water heaters. I appreciate the clear explanation of the code requirements and how they relate to different system setups. It’s reassuring to know that there’s a logical basis for whether or not a thermal expansion tank is needed.

Your welcome. I am glad the information was helpful.

I’m running a hybrid setup: NG Tankless filling an Ariston 4 gallon to a mixing valve to capture and mitigate the cold water sandwich. The Tankless feeds 134 degree temp to Ariston, which I aim to keep at or near that temp before mixing valve adjusts to 115. While the Tank is holding hot(expanded) water, it’s being supplied by hot water and should only be adding heat to maintain the quantity of water.

Yet, I’m on my second Ariston that’s leaked, and moving to my third shortly. I’m wondering if the upper/lower bounds of the heat/cooling in the Ariston has been enough to stress the vessel. What I am noticing is the Anode in the Ariston is rapidly deteriorating (12-15 months) due to the high flow.

Any thoughts on this setup? There’s no recirculation going on.

That is an interesting setup. I do not have experience with the Ariston brand.

Could thermal expansion be contributing to high pressure in the system, which is connected to the 4-gallon tank? Have you checked the operating pressure? If there is a pressure problem, adding a thermal expansion tank to the system may help.

The Ariston is intended for point-of-use application. It probably has 1/2-inch connections. Are the flow rates high enough to cause erosion in the tank or the connections?

Thank you for your thoughts Roger, much appreciated. In reply:

– I haven’t been able to observe the noises coinciding with the pump turning on and off. The aquastat is controlled by a smart plug which turns off between 10.30pm and 6.30am and we sometimes hear the noises in the night

– The pump is a a Laing SMT303, rated at 33W and the aquastat is a Honeywell L6006C, set to 10F below the set output temprature (105F and 115F respectively)

Is there any downside to adding an expansion tank? If not I will give that a try next.

Thanks again!

What about the situation where there is a recirculation loop and no storage tank? a circulator runs on a timer and the water is heated due to flow from the circulator, but no faucet is open because of the circulator schedule

Great question Anthony. Any answers to this out there?

I would love to know this answer too! We just had a Ru98i with recerc pump with no storage tank installed. I was wondering if we needed the pressure tank?

Whether a pressure tank is needed depends upon whether a check valve or pressure reducer is installed on the supply line. Local codes may also require a tank. I recommend contacting a local plumbing contractor for advice and direction.

We have this set up; a Nortiz EZ111 hot water heater with a recirculation loop controlled by an aquastat. We have started to hear the pipes knocking and ‘grating’. Could the addition of an expansion tank solve the problem? Thank you.

Andrew,

A question:

Do the knocking and grating noises coincide with the pump starting or stopping? If so, the addition of an expansion tank may alleviate the noise problem. It also may be an oversized pump. If not, the noises may be due to thermal expansion in the piping – due to the cycling. The piping may be too constrained by pipe supports. If this is the source of the noise, removing or loosening the supports may help.

Another option to consider is letting the recirc pump run continuously without the aquatstat. I know that energy conservation codes typically require the pump to be controlled by the aquastat, but no recirc flow intermittently increases the risk of legionella growth.